ABOUT US

We recognize the importance of resources for future generations.

We recognize the importance of resources for future generations.

Onbridge aims to complete the value chain of the battery

resource recycling cycle—from manufacturing and evaluation

to disposal—for the benefit of future generations,

the environment, and resource sustainability.

Our lettermark embodies our commitment to serving as

the bridge (bridge) that initiates (on) the transfer of

finite value to future generations.

Onbridge aims to complete the value chain of the battery resource recycling cycle—from manufacturing and evaluation to disposal—for the benefit of future generations, the environment, and resource sustainability. Our lettermark embodies our commitment to serving as the bridge (bridge) that initiates (on) the transfer of finite value to future generations.

Onbridge aims to complete the value chain of the battery resource recycling cycle—from manufacturing and evaluation to disposal—for the benefit of future generations, the environment, and resource sustainability.

Our lettermark embodies our commitment to serving as the bridge (bridge) that initiates (on) the transfer of finite value to future generations.

Our lettermark embodies our commitment to serving as the bridge (bridge) that initiates (on) the transfer of finite value to future generations.

Business

Pro-environmental

We conduct our business based on the battery resource recycling cycle to promote environmentally friendly resource utilization.

Battery Manufacturing

Battery Manufacturing

Inspect new batteries and collect initial data during the manufacturing stage

• High-Efficiency Battery Module Cycler

• High-Efficiency Battery Pack Cycler

• High-Efficiency Battery Pack Cycler

Battery

Usage

Usage

Assess the performance of in-use batteries and gather mid-term data.

•

Electric Vehicle Battery Performance Evaluation System

Reuse &

Re-manufacturing

Test the performance of used batteries and collect end-of-life data.

• Used Battery Residual Performance Evaluation System (H/W & S/W)

• High-Precision High-Efficiency Premium Inspection Equipment

• High-Precision High-Efficiency Premium Inspection Equipment

Recycling & Disposal

Ensure safe discharge and collect end-stage data.

• Electrical Discharge Equipment

Business

Pro-environmental

We conduct our business based on the battery resource recycling cycle to promote environmentally friendly resource utilization.

Battery Manufacturing

Battery Manufacturing

Inspect new batteries and collect initial data during the manufacturing stage

• High-Efficiency Battery Module Cycler

• High-Efficiency Battery Pack Cycler

• High-Efficiency Battery Pack Cycler

Battery Usage

Battery Usage

Assess the performance of in-use batteries and gather mid-term data.

• Electric Vehicle Battery Performance Evaluation System

Reuse and

Remanufacturing

Test the performance of used batteries and collect end-of-life data.

• Used Battery Residual Performance Evaluation System (H/W & S/W)

• High-Precision High-Efficiency Premium Inspection Equipment

• Electric Vehicle Battery Performance Evaluation System

• High-Precision High-Efficiency Premium Inspection Equipment

• Electric Vehicle Battery Performance Evaluation System

Recycling and Disposal

Recycling and Disposal

Ensure safe discharge and collect end-stage data.

• Electrical Discharge Equipment

Milestone

Precise

We aim to develop precise equipment

and create a solution for predicting future battery

performance based on accurate data.

and create a solution for predicting future battery

performance based on accurate data.

Step 1

Equipment Development and Data Collection

• Develop in-house Cycler capable of precise measurements to collect data throughout the entire battery lifecycle.

• High-Efficiency Battery Pack Cycler.

• High-Efficiency Battery Pack Cycler.

Step 2

Data Analysisand Algorithm

Development

• Research on electrical degradation factors.

• Research on chemical degradation factors.

• Develop algorithms based on five key characteristics: DCIR, ACIR, chemical composition, manufacturer-specific characteristics, and BMS data.

• Research on chemical degradation factors.

• Develop algorithms based on five key characteristics: DCIR, ACIR, chemical composition, manufacturer-specific characteristics, and BMS data.

Step 3

AI Training and Model Completion

• Develop models based on battery characteristics and driver-specific traits.

• Implement machine learning and simulations.

• Implement machine learning and simulations.

Step 4

Total Solution Integration

• Develop models tailored to the characteristics of traditional mobility.

• Continue machine learning and simulation.

• Finalize product development.

• Continue machine learning and simulation.

• Finalize product development.

Milestone

Precise

We aim to develop precise equipment and create a solution for predicting future battery performance based on accurate data.

Step 1

Equipment Development and Data Collection

• Develop in-house Cycler capable of precise measurements to collect data throughout the entire battery lifecycle.

• High-Efficiency Battery Pack Cycler.

• High-Efficiency Battery Pack Cycler.

Step 2

Data Analysis and Algorithm Development

• Research on electrical degradation factors.

• Research on chemical degradation factors.

• Develop algorithms based on five key characteristics: DCIR, ACIR, chemical composition, manufacturer-specific characteristics, and BMS data.

• Research on chemical degradation factors.

• Develop algorithms based on five key characteristics: DCIR, ACIR, chemical composition, manufacturer-specific characteristics, and BMS data.

Step 3

AI Training and Model Completion

• Develop models based on battery characteristics and driver-specific traits.

• Implement machine learning and simulations.

• Implement machine learning and simulations.

Step 4

Total Solution Integration

• Develop models tailored to the characteristics of traditional mobility.

• Continue machine learning and simulation.

• Finalize product development.

• Continue machine learning and simulation.

• Finalize product development.

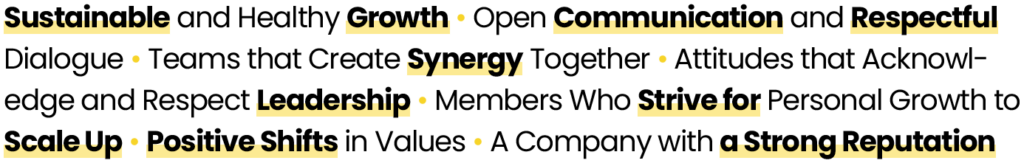

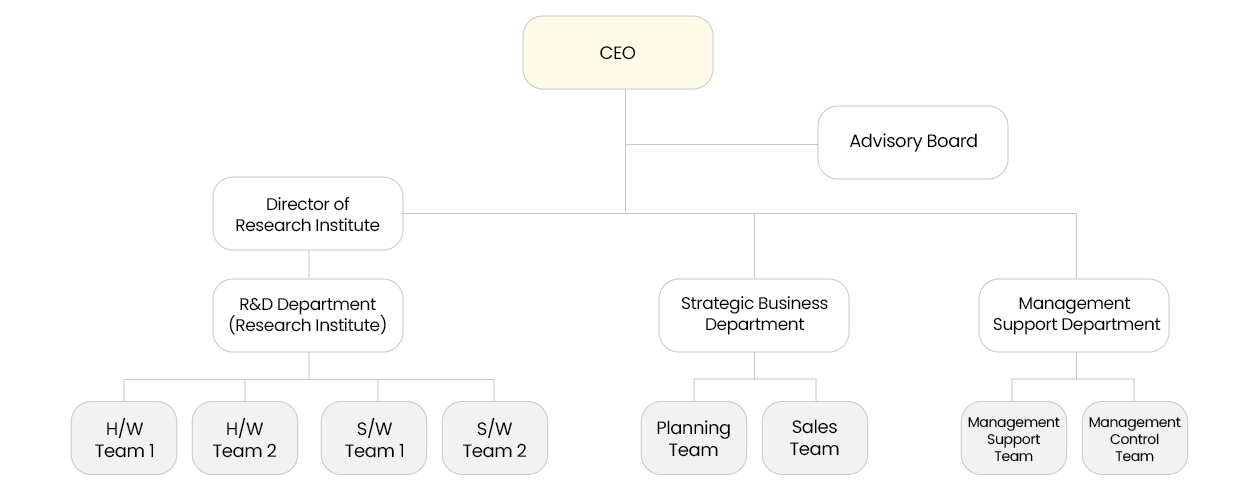

Team

Sustainable

Onbridge aims to be a company that continually pursues positive and sustainable growth.

View Our Organizational Structure

Team

Sustainable

Onbridge aims to be a company that continually pursues positive and sustainable growth.

View Our Organizational Structure

Our journey

2024.

Second half

03.

03.

300KW (1000V/300A) Battery Pack Cycler:

Scheduled for release after domestic certification testing

Opening of Factory and Research Institute

Scheduled for release after domestic certification testing

Opening of Factory and Research Institute

2023.

10.

06.

05.

04.

06.

05.

04.

30KW (100V/300A) Battery Module Cycler: Initiation of research and development

Acquisition of Factory and Research Institute Site: 495.87 square meters site in Daegu

High-Precision, High-Efficiency Premium Cycler: Initiation of research and development

300KW (1000V/300A) Battery Pack Cycler Prototype: Development completed

Acquisition of Factory and Research Institute Site: 495.87 square meters site in Daegu

High-Precision, High-Efficiency Premium Cycler: Initiation of research and development

300KW (1000V/300A) Battery Pack Cycler Prototype: Development completed

2022.

12.

05.

05.

300KW Power Module Supply Contract Secured

Onbridge Inc.: Corporate establishment

Development of 30KW / 300KW Battery Module/Pack Cycler: Initiation of the project

Onbridge Inc.: Corporate establishment

Development of 30KW / 300KW Battery Module/Pack Cycler: Initiation of the project

Our journey

2024.

Second half

03.

03.

300KW (1000V/300A) Battery Pack Cycler:

Scheduled for release after domestic certification testing

Opening of Factory and Research Institute

Scheduled for release after domestic certification testing

Opening of Factory and Research Institute

2023.

10.

06.

05.

04.

06.

05.

04.

30KW (100V/300A) Battery Module Cycler: Initiation of research and development

Acquisition of Factory and Research Institute Site: 495.87 square meters site in Daegu

High-Precision, High-Efficiency Premium Cycler: Initiation of research and development

300KW (1000V/300A) Battery Pack Cycler Prototype: Development completed

Acquisition of Factory and Research Institute Site: 495.87 square meters site in Daegu

High-Precision, High-Efficiency Premium Cycler: Initiation of research and development

300KW (1000V/300A) Battery Pack Cycler Prototype: Development completed

2022.

12.

05.

05.

300KW Power Module Supply Contract Secured

Onbridge Inc.: Corporate establishment

Development of 30KW / 300KW Battery Module/Pack Cycler: Initiation of the project

Onbridge Inc.: Corporate establishment

Development of 30KW / 300KW Battery Module/Pack Cycler: Initiation of the project

Our journey

2024.

Half 2

03.

03.

300KW (1000V/300A) Battery Pack Cycler: Scheduled for release after domestic certification testing

Opening of Factory and Research Institute

Opening of Factory and Research Institute

2023.

10.

06.

05.

04.

06.

05.

04.

30KW (100V/300A) Battery Module Cycler: Initiation of research and development

Acquisition of Factory and Research Institute Site: 495.87 square meters site in Daegu

High-Precision, High-Efficiency Premium Cycler: Initiation of research and development

300KW (1000V/300A) Battery Pack Cycler Prototype: Development completed

Acquisition of Factory and Research Institute Site: 495.87 square meters site in Daegu

High-Precision, High-Efficiency Premium Cycler: Initiation of research and development

300KW (1000V/300A) Battery Pack Cycler Prototype: Development completed

2022.

12.

05.

05.

300KW Power Module Supply Contract Secured

Onbridge Inc.: Corporate establishment

Development of 30KW / 300KW Battery Module/Pack Cycler: Initiation of the project

Onbridge Inc.: Corporate establishment

Development of 30KW / 300KW Battery Module/Pack Cycler: Initiation of the project

Office&Works

H.Q

3F, Daegu CCEI, 51 Hoam-ro, Bukgu, Daegu, Korea

3F, Daegu CCEI, 51 Hoam-ro, Bukgu, Daegu, Korea

Seoul Office

13F, FRONT1, 122 Mapodae-ro, Mapogu, Seoul, Korea

13F, FRONT1, 122 Mapodae-ro, Mapogu, Seoul, Korea

Lab&Factory

#509, D-center 1976, 307 Waryong-ro, Seogu, Daegu, Korea

#509, D-center 1976, 307 Waryong-ro, Seogu, Daegu, Korea

H.Q

3F, Daegu CCEI, 51 Hoam-ro, Bukgu, Daegu, Korea

Seoul Office

13F, FRONT1, 122 Mapodae-ro, Mapogu, Seoul, Korea

Lab&Factory

#509, D-center 1976, 307 Waryong-ro, Seogu, Daegu, Korea

H.Q

3F, Daegu CCEI, 51 Hoam-ro, Bukgu, Daegu, Korea

Seoul Office

13F, FRONT1, 122 Mapodae-ro, Mapogu, Seoul, Korea

Lab&Factory

#509, D-center 1976, 307 Waryong-ro, Seogu, Daegu, Korea

You must be logged in to post a comment.